We are pleased to present Caffaro Sp. z o. o. Sp. k.,

a company with rich traditions, whose origins date back to 2008.

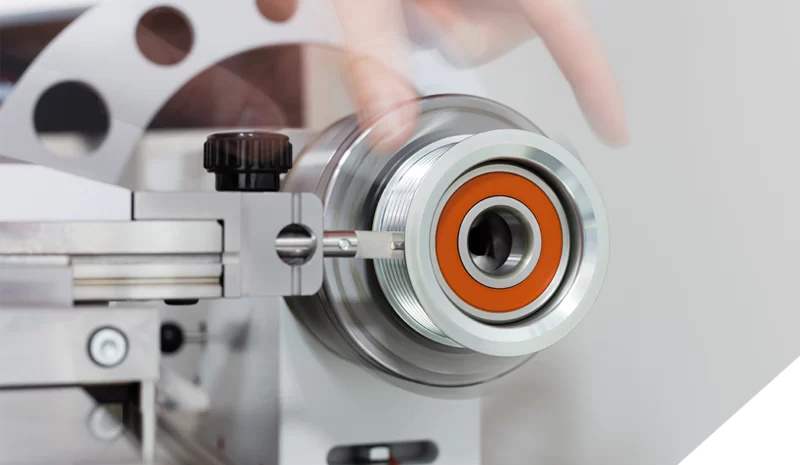

Caffaro is a Polish manufacturer of pulleys and tensioners. Our offer includes nearly 1,200 different references for passenger cars, delivery vans, trucks and tractors.

The company also offers a wide range of services and production of parts according to individual designs of our clients for the automotive, railway and construction industries.

By renting larger and larger spaces in various locations, in 2014 we decided to purchase land to build our own production hall, which was an important step in our history.

Thanks to the implementation of international standards in the field of management, environmental protection and quality in the automotive, railway and construction industries, our products meet the highest standards.

While implementing numerous projects, we have created groundbreaking pulleys for combustion engines, micro and mild hybrid ones and have developed process innovations that have been patented.

We have our own laboratory equipped with the latest equipment and modern machinery. Currently, production takes place in halls with a total area of over 7,000 m² owned by the Company.